![]()

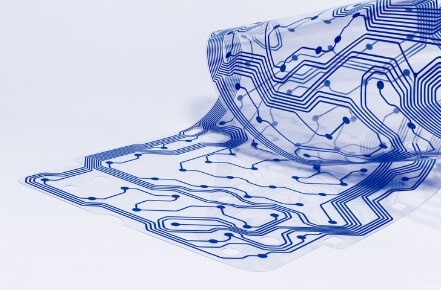

Printed electronics is an exciting and rapidly growing field that merges traditional printing techniques with modern electronics manufacturing. At its core, it refers to the use of printing technologies—such as screen printing, inkjet printing, and aerosol jet printing—to create electronic circuits and devices. Unlike traditional subtractive fabrication methods used in semiconductor manufacturing, printed electronics is largely additive, meaning materials are deposited only where needed. This allows for new design possibilities, lower material waste, and often lower manufacturing costs.

A New Way to Make Electronics

Imagine printing a circuit onto a sheet of plastic, paper, or even fabric—just like printing ink on paper. That’s the basic idea behind printed electronics. Instead of etching metal onto silicon wafers, manufacturers use specialized inks made from conductive materials like silver, carbon, or conductive polymers to create patterns on flexible surfaces.

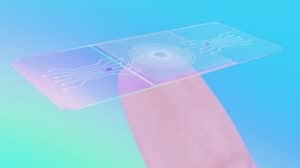

Printed electronics enables thin, lightweight, and flexible devices, which is a game-changer in applications where traditional electronics are too bulky or rigid. Think of wearable sensors that conform to the skin, disposable medical test strips, or smart labels that track products in transit.

Printed Electronics – Key Application Areas

Printed electronics is not just a niche technology; it is being adopted across many industries. Here are a few prominent application areas:

Wearable Technology

- Flexible sensors for health and fitness monitoring

- Printed antennas and interconnects in smart textiles

Medical Devices

- Biosensors for glucose and hydration monitoring

- Disposable diagnostic devices

Consumer Electronics

- Flexible displays and touch sensors

- Printed batteries and energy harvesters

Smart Packaging and Labels

- NFC/RFID tags

- Temperature or freshness indicators

Automotive and Transportation

- Printed heating elements (e.g., for windshields or seats)

- Capacitive touch sensors for dashboards

Energy

- Printed solar cells

- Printed batteries and supercapacitors

Common Printing Methods

Printed electronics relies on adapting various printing techniques to deposit functional inks. Each method has its own advantages depending on the resolution required, ink properties, and scalability.

-

Screen Printing

- A stencil-based process ideal for thicker layers and robust conductive traces. Common in large-scale production.

-

Inkjet Printing

- Digital and maskless; excellent for prototyping and small-scale runs. Offers fine resolution but slower throughput.

-

Aerosol Jet Printing

- Ideal for fine lines and 3D surfaces. Often used for high-resolution and complex geometries.

-

Gravure and Flexographic Printing

- Roll-to-roll compatible; very fast and suitable for high-volume production. Often used for packaging-related electronics.

-

Slot Die and Blade Coating

- Suitable for uniform films, such as dielectric layers or active layers in solar cells.

Materials Used in Printed Electronics

Printing electronics is not just about putting ink on a surface—it’s about depositing the right materials in the right structure. Common types of functional inks include:

- Conductive Inks: Often based on silver nanoparticles, copper, or carbon. These form the conductive pathways in circuits.

- Semiconducting Inks: Organic molecules or metal oxides used in transistors and solar cells.

- Dielectric Inks: Insulating materials used to separate conducting layers.

- Sensing Inks: Specialized materials that respond to pressure, temperature, humidity, or biochemicals.

Advantages of Printed Electronics

- Flexibility: Printed electronics can be applied to bendable, stretchable, and conformable surfaces.

- Lightweight and Thin: Suitable for applications like smart labels or wearable patches.

- Cost-Effective: Additive printing reduces material waste.

- Customizability: Digital printing methods allow for easy prototyping and design iteration.

- Scalability: Many printing techniques are roll-to-roll compatible, allowing mass production.

The Evolution of Printed Electronics (2000–Present)

The concept of printed electronics is not new—it traces back to printed circuit boards (PCBs). However, the modern version took off in the early 2000s with advances in nanomaterials, printable semiconductors, and flexible substrates.

- Early 2000s: Research focused on organic semiconductors and low-temperature processing. Prototypes included printed RFID tags and simple displays.

- 2010s: Commercialization picked up with products like smart packaging, printed sensors, and OLED displays. Companies began scaling up with roll-to-roll manufacturing.

- 2020s and Beyond: Integration with AI, 5G, and the Internet of Things (IoT) is driving demand. Developments in hybrid electronics—combining printed components with traditional chips—are expanding functionality. See: Photonic curing and materials like graphene.

Challenges and Future Outlook

- Standardization: Lack of universal design and testing standards.

- Durability: Printed components must survive bending, washing, and environmental exposure.

- Material Stability: Inks must maintain performance over time.

Looking ahead, printed electronics is expected to play a critical role in:

- Smart cities

- Personalized healthcare

- Sustainable packaging

- Next-generation displays

Conclusion

Printed electronics represents a shift in how we think about and manufacture electronics. It brings the possibility of merging form and function into everyday objects—making electronics more accessible, affordable, and integrated into our lives.