1. Custom Printed Strain Gauges

Strain gauges play a critical role in structural monitoring, wearable technology, robotics, and flexible electronics. Traditional strain gauges, though widely used, are constrained by rigid substrates, complex assembly processes, and lack of customization. Advances in printed electronics — particularly with conductive nanoparticle inks — are enabling a new class of digitally fabricated strain sensors that are lightweight, flexible, and application-specific.

This white paper reviews the development and validation of printed strain gauges using silver nanoparticle inks from NovaCentrix. A few academic studies are highlighted:

- Two from the University of Louisville (ref 1, ref 2) demonstrating aerosol jet printing (AJP) of strain gauges using JS-A426 ink, including gauge design, sintering optimization, and gauge factor measurement.

- One from the University of Texas at San Antonio (ref 3) using JS-A102A ink and another from University of Novi Sad (ref 4) using JS-B25HV and JS-B15P with inkjet (drop-on-demand) printing to rapidly fabricate geometrically varied sensors in a single pass.

- Two additional studies showcase real-world applications: a Delta robot with embedded strain sensing using JS-B25P (ref 5) and a tactile skin for robotic sensing using JS-A426 (ref 6).

Together, these studies demonstrate how NovaCentrix inks support rapid prototyping, customizable sensor design, and performance competitive with commercial gauges, across multiple printing platforms.

2. Introduction and Background

Strain gauges are fundamental tools for measuring mechanical deformation in structures and materials. They operate on a simple principle: when a conductive element is stretched or compressed, its geometry changes, which alters its electrical resistance. This resistance change can be measured to quantify strain.

Traditional strain gauges, typically composed of etched metal foil adhered to a polymer backing, are effective but suffer from key limitations: rigid substrate dependence, adhesive mounting, complex manufacturing and assembly, and limited design freedom.

Printed electronics presents a transformative opportunity. By digitally patterning conductive inks directly onto flexible substrates, it is now possible to customize sensor geometry at the software level, print onto curved or soft surfaces, and rapidly iterate through designs.

NovaCentrix offers a suite of metal nanoparticle inks — including silver, copper, and alloy systems — tailored to specific print platforms. Their inks are designed to meet the stringent requirements of printed electronics.

3. NovaCentrix Inks for Strain Gauges

NovaCentrix’s conductive inks are engineered for digital deposition and post-print processing, supporting advanced manufacturing of printed sensors. Multiple silver nanoparticle inks from NovaCentrix have been validated in academic research for use in strain gauge applications.

- JS-A426: AJP-optimized silver ink for fine-line printing on flexible substrates.

- JS-A102A, JS-B25P, JS-B25HV and JS-B15P: Inkjet-optimized silver ink for rapid prototyping.

4. Case Studies: Printed Strain Gauges Using NovaCentrix Inks

4.1 JS-A426 via Aerosol Jet Printing (University of Louisville)

Two studies from the University of Louisville demonstrated the use of JS-A426 with aerosol jet printing to fabricate custom strain gauges on Kapton.

Gauge Factor (GF) is a key figure of merit for strain gauges and is defined as:

GF = (ΔR / R) / ε

Where ΔR is the change in resistance, R is the original resistance, and ε is the applied strain. A higher GF indicates greater sensitivity. Most commercial metal foil gauges have a GF between 2.0 and 2.2. Printed gauges using NovaCentrix inks have demonstrated GF values in the range of 1.7 to 2.0.

Key Results:

- Printer: Optomec AJP

- Line Width: 50–60 μm

- Sintering: 200–240 °C for 18–24 hrs

- Conductivity: ~7.05×10⁶ S/m

- Gauge Factor: 1.85 (2021), 1.74 (2023)

The 2023 follow-up also introduced a conductivity prediction model based on sintering conditions, improving process control for diverse substrates.

4.1.2 JS-A426 for Tactile Sensing on Flexible Substrates

This work expanded the use of JS-A426 to fabricate an omnidirectional tactile sensor embedded in PDMS for robotic skins. Using a star-shaped pattern and encapsulation, the sensor achieved robust performance under 5000 cycles with a gauge factor of ~1.85, showing its viability for dynamic robotic environments.

4.2 JS-A102A via Inkjet Drop-on-Demand (University of Texas at San Antonio)

This study used JS-A102A with a Dimatix DOD inkjet printer to explore rapid sensor fabrication. Multiple geometries were printed on Kapton, achieving resistances between 2.3–7.2 Ω after sintering at 50°C and 150°C in sequence. This approach demonstrated fast turnaround and consistency, ideal for prototyping strain sensors in varied layouts.

4.3 JS-B25HV and JS-B15P via Inkjet Printing (University of Novi Sad)

Researchers compared performance of JS-B25HV and JS-B15P inks printed with professional and desktop inkjet systems. On polyimide and PET, the sensors achieved GF values from 1.58 to 2.03 depending on ink, substrate, and layer count. Durability and stability were good over short-term, with mild resistance drift over 2+ months.

5. Real-World Application: Printed Strain Gauges in an Origami-Based Delta Robot

A team at Istanbul Technical University integrated printed strain gauges using JS-B25P into a foldable Delta robot. The sensors were printed on PET and embedded in origami joints for angle measurement. They successfully tracked 0°–90° motion via resistance change, enabling analog feedback for closed-loop control in lightweight robotic systems.

6. Real-World Application: JS-A426 for Tactile Sensing in Robotic Skins

A star-shaped strain gauge using JS-A426 was printed on flexible Kapton and embedded in PDMS to act as a tactile skin sensor. Designed for omnidirectional sensitivity, it achieved linear and repeatable response under sinusoidal and step inputs. The sensor demonstrated excellent durability and system integration capability for soft robotics.

7. Summary and Outlook

Across a diverse set of academic and applied research studies, NovaCentrix silver nanoparticle inks have proven effective for fabricating high-performance, flexible strain gauges using multiple digital printing methods. From aerosol jet to inkjet, and from Kapton to PET, these inks have shown reliable conductivity, repeatable gauge factor values in the range of 1.7–2.0, and integration into real-world robotic systems and tactile sensors.

The ability to customize geometry, print directly onto flexible substrates, and use low-cost printing systems makes these inks attractive for rapid prototyping, production, and novel application areas such as soft robotics, wearables, and structural health monitoring.

Future directions include:

- Using photonic sintering (e.g., PulseForge) for ultra-low thermal budget applications.

- Combining strain sensors with additional functions (e.g., temperature, pressure).

- Developing libraries of validated sensor geometries for faster deployment in OEM and research settings.

NovaCentrix’s expanding materials portfolio and ecosystem support make it possible to quickly go from lab-scale innovation to scalable manufacturing.

8. References

- Ratnayake et al., IEEE FLEPS, 2021

- Ratnayake et al., IEEE JFlex, 2023

- Dipon et al., FERROELECTRICS, 2023

- Zlebic et al., Electronics and Energetics, 2016

- Kalafat, Hittite Journal of Science and Engineering, 2022

- Olowo et al., IEEE Journal on Flexible Electronics, 2023

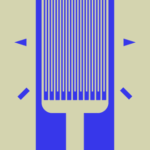

Image Credits

Image source: Strain gauge illustration, used under CC BY-SA 2.5.